Imagine this: It's Monday morning, 8:00 a.m. Your phone is ringing for the fifth time, three customers are waiting at reception, and your best mechanic has called in sick. At the same time, you have to figure out which lift is free, who is working on which vehicle, and whether Mr. Müller's vehicle inspection appointment was today or tomorrow. Sound familiar? This is precisely where modern workshop planning comes in – and this is precisely where CATAMA software makes the crucial difference for automotive workshops in Germany, Austria, and Switzerland.

By 2026, the digitalization of workshop planning will no longer be a luxury, but a business necessity. While traditional planning methods using whiteboards, Excel spreadsheets, or paper lists are reaching their limits, CATAMA offers a cloud-based, comprehensive solution that intelligently connects workshop planning

Key Takeaways

- ✅ Real-time planning : CATAMA enables cloud-based workshop planning with instant synchronization for all employees – no more double bookings.

- ⏱️ Time savings of 30-40% : Automatic time slot scheduling, digital time tracking and efficiency analyses drastically reduce administrative effort.

- 📊 Resource optimization : Intelligent allocation of mechanics, lifts, test benches and loaner vehicles maximizes utilization

- 💰 Increased ROI : Direct time tracking against orders, automatic billing, and employee evaluations improve profitability.

- 🔄 Seamless integration : Full integration with invoicing, inventory management, Stakis 4.0 and other industry interfaces

Why modern workshop planning will be indispensable in 2026

The challenges of traditional planning methods

Automotive repair shops today face more complex demands than ever before. The average shop juggles 15-25 orders daily, 4-8 mechanics, multiple lifts, specialized tools, and increasingly demanding customer expectations. Traditional planning methods quickly reach their limits in this environment

Typical problems without digital workshop planning:

- 🔴 Double bookings of resources (lifting platforms, special tools)

- 🔴 Inefficient utilization due to lack of overview

- 🔴 Time wasted due to manual appointment scheduling

- 🔴 Lack of transparency regarding employee workload

- 🔴 No traceability of time spent

- 🔴 Delayed billing due to lack of time tracking

A study from 2025 shows that workshops without digital planning software waste an average of 8-12 hours per week on administrative planning tasks – time that could be directly invested in productive workshop work[7].

The business case for digital workshop planning

Investing in professional workshop software like CATAMA pays for itself within just a few months. Let's consider an average workshop with 5 mechanics:

| Key figure | Without CATAMA | With CATAMA | saving |

|---|---|---|---|

| Planning effort/week | 10 hours | 3 hours | 7 hours |

| Average occupancy | 68% | 87% | +19% |

| Incorrect bookings/month | 12-15 | 0-2 | ~13 |

| Billing delay | 3-5 days | Immediately | 100% |

| Employee satisfaction | Medium | High | ↑ |

With an average hourly rate of €95, a 19% increase in capacity utilization for 5 mechanics translates to an additional revenue of over €3,500 per week – that's over €180,000 in additional annual revenue.

How car repair shops save time and money with CATAMA software is repeatedly demonstrated in practice: The digitization of workshop planning is not a cost center, but an investment with a measurable return on investment.

CATAMA Workshop Planner: Core functions for maximum efficiency

Intelligent task assignment to employees and departments

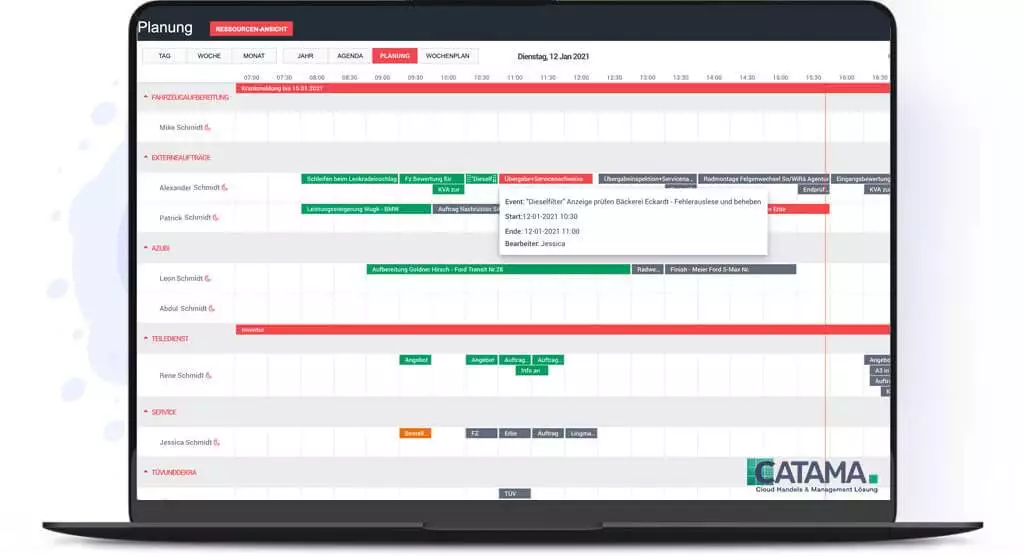

The CATAMA workshop planner and scheduler revolutionizes daily work organization through intelligent, rule-based order assignment. The system automatically takes the following into account:

Employee-specific factors:

- ✓ Qualifications and certifications (e.g. high-voltage authorization)

- ✓ Specializations (engine technology, bodywork, electrics)

- ✓ Current occupancy and available capacity

- ✓ Vacation planning and absences

- ✓ Break times and legal working hours

Department-specific planning:

- ✓ Separate planning for workshop, bodywork, tire service

- ✓ Resource allocation according to departmental capacity

- ✓ Comprehensive coordination for complex projects

- ✓ Cross-departmental evaluations

The new vacation planning feature for 2026 has been integrated directly into user settings, allowing for even more precise management of employee availability[1]. This automatically prevents tasks from being assigned to absent employees.

Practical example: Müller GmbH workshop in Nuremberg reduced its throughput times by 23% through intelligent order allocation. "Previously, I had to spend 30 minutes every morning figuring out who would get which order," reports workshop manager Thomas Müller. "Now CATAMA suggests the optimal distribution – based on qualifications and current workload."

Digital time tracking: Two flexible methods

CATAMA offers two proven methods of time recording that can be perfectly integrated into different workshop processes[3]:

Method 1: Click-based time tracking

- Direct data entry on behalf of the client via tablet or desktop

- One-click start/stop function

- Automatic break detection

- Ideal for workshops with fixed workstations

Method 2: QR Code Scanner Integration

- Scanning order-specific QR codes

- Mobile data collection directly at the vehicle

- Especially suitable for large workshops

- Minimal time commitment for employees

The recorded times are booked against the orders in real time and are immediately available for invoicing. This eliminates the problem of “forgotten working hours”, which costs many workshops an average of 5-8% of their revenue [8].

Time tracking workflow in CATAMA:

- Employee starts time tracking (click or QR code)

- The system automatically books time against the order

- In case of interruptions: Automatic break recording

- Conclusion: Time will be directly billed

- Analysis: Target/actual comparison available in real time

Efficiency evaluation and employee analysis

A key competitive advantage of CATAMA workshop planning lies in its comprehensive evaluation capabilities. The system offers detailed insights into:

Order vs. Time Tracking – The Target-Actual Comparison:

- Comparison of calculated time vs. actual time required

- Real-time identification of deviations

- Basis for recalculation and price adjustments

- Identifying training needs

Employee evaluations:

- Productivity per employee (billable vs. non-billable hours)

- Average processing times by order type

- Qualification gaps through time comparisons

- Performance-based incentive principles

Efficiency dashboards:

- Total workshop utilization

- Resource utilization (lifting platforms, test benches)

- Throughput times by vehicle type

- Bottleneck analyses

These analyses enable workshop managers to make data-driven decisions. efficient automotive workshop ERP software provides all the necessary key performance indicators for professional controlling.

Automatic time slot scheduling and appointment reminders

Automatic time slot scheduling is one of the most intelligent features of the CATAMA workshop planner. Based on various parameters, the system calculates the optimal appointment slots:

Factors considered in time slot scheduling:

- Estimated order duration (from preliminary costing)

- Available employees with suitable qualifications

- Free lifting platforms and special tools

- Already booked appointments

- Buffer times for unforeseen delays

- Company holidays and public holidays[3]

The improved appointment slot search function from update V26-2 makes it possible to identify available time slots even faster [6]. Workshop managers can thus find the next available appointment for a customer order in seconds.

Automatic appointment reminders:

- SMS or email notifications to customers

- Configurable lead times (e.g. 24 hours before the appointment)

- Reduction of no-shows by up to 75%

- Automatic reminders for service appointments

The new “Next Service” feature can now be entered and saved directly when creating an invoice[1], enabling seamless integration between invoicing and future scheduling.

Resource planning: More than just employees

Modern workshop planning means not only coordinating employees, but also the holistic management of all operational resources. CATAMA offers comprehensive functions for:

Lifting platform management:

- Real-time overview of available/occupied lifting platforms

- Automatic assignment based on vehicle type

- Maintenance intervals and inspection deadlines

- Occupancy statistics

Test bench coordination:

- Scheduling vehicle inspection (HU/AU) appointments

- Integration with testing organizations

- Capacity planning for main inspections

- Documentation and archiving

Rental vehicle management:

- Availability and booking status

- Automatic assignment for long-term orders

- Handover and return protocols

- Damage documentation

Break planning and compliance with working hours:

- Automatic consideration of legally mandated break times

- Planning in compliance with working time law

- Shift planning for multi-shift operations

- Overtime recording

The comprehensive resource management with detailed real-time utilization displays[3] gives workshop managers a complete overview of all available capacities at all times.

Cloud-based real-time synchronization

A key advantage of CATAMA over on-premises solutions is its cloud-based architecture. All planning changes are visible to all employees in real time [3]:

Advantages of the cloud solution:

- 🌐 Access from anywhere (office, workshop, home office)

- 🔄 Automatic synchronization without manual intervention

- 💾 Automatic backups – no data loss

- 🔐 Highest security standards (GDPR compliant)

- 📱 Mobile use on tablets and smartphones

- ⚡ No IT infrastructure required

The cloud-based automotive workshop software enables teams to work in perfect coordination – even if the workshop manager is currently on-site at the customer's location or a mechanic is working in the field.

Integration into the entire workshop workflow

From appointment request to billing

The true strength of CATAMA workshop planning lies in its seamless integration with all other business processes. The entire workflow is digitally mapped:

1. Appointment request and booking

- Customer calls or uses online appointment booking

- The system displays available time slots based on the order description

- Automatic confirmation email with appointment reminder

- The appointment appears immediately in the workshop planner

2. Order placement and preliminary costing

- Digital order entry with vehicle data (OCR document scanner)

- Automatic calculation based on repair catalogs

- Integration with Stakis 4.0, REPDOC, WMKAT for spare part prices

- Offer creation and customer approval

3. Workshop planning and allocation

- Automatic or manual assignment to qualified mechanics

- Resource reservation (lifting platform, tools)

- Drag & drop function for flexible rescheduling

- Consideration of priorities and rush orders

4. Implementation and time recording

- Mechanic starts time tracking on the job

- Real-time tracking of work progress

- Documentation of additional work

- Photo documentation if required

5. Billing and post-calculation

- Automatic transfer of recorded times to invoice

- Target-actual comparison for post-calculation

- Invoice creation with one click

- DATEV export for accounting

The two new optional fields “Workshop stay” and “Header text” in the invoice and quotation editor[1] enable even more detailed documentation and customer communication.

Interfaces to industry systems

CATAMA is not an isolated, standalone solution, but integrates seamlessly into the existing IT landscape of automotive businesses:

Spare parts catalogs and suppliers:

- Stakis 4.0 integration for direct access to the Stahlgruber product range

- Partslink24 interface for spare parts procurement

- REPDOC and WMKAT for repair information

- Mercedes-Benz WebParts Shopping Cart Import

Accounting and Finance:

- DATEV interface for seamless data export

- E-invoicing functionality (XRechnung-compliant)

- Automatic account assignment and booking suggestions

- Accounts receivable management

Vehicle data and manufacturer:

- Manufacturers' online service book integration

- OCR technology for vehicle registration document capture

- KBA database for vehicle identification

- Mileage history in CRM[6]

These comprehensive interfaces make CATAMA a true all-in-one solution that covers all areas of workshop operations.

Mobile access and flexibility

Mobile usage will become increasingly important in 2026. CATAMA offers full functionality on all devices:

Tablet use in the workshop:

- Optimized interface for touch operation

- Time recording directly on the vehicle

- Photo documentation with integrated camera

- Access to repair manuals and circuit diagrams

Smartphone app for on the go:

- Schedule overview for workshop managers

- Quick status queries

- Customer communication from Überwegs

- Push notifications for important events

Desktop full version:

- Complete administrative functions

- Detailed analyses and reports

- Configuration and system settings

- Multi-monitor support for maximum overview

Cancellation management and calendar optimization

An often overlooked but important feature is intelligent cancellation management. With update V26-4, a new automatic "Cancelled" status was introduced[1]:

Automatic cancellation logic:

- Appointments for cancelled orders are automatically marked

- Appointments remain visible in the calendar (for traceability)

- Automatic removal from active workshop planning

- Release of reserved resources

- Historical traceability

In addition, a bug in the recalculation of appointment duration during drag & drop in the calendar was fixed[1], which further improves planning accuracy.

The improved linking of customer and vehicle information in the calendar[1] makes it possible to grasp all relevant information at a glance – without having to switch between different views.

Pricing models and return on investment

CATAMA Editions Overview 2026

CATAMA offers various editions tailored to different farm sizes. According to current pricing information, all editions include automatic updates at no additional cost starting in 2026 [5]

CATAMA Professional Suite

- For established workshops (8-15 employees)

- Comprehensive workshop planning

- Department planning

- Extended interfaces

- From €99/month

CATAMA Enterprise Suite

- For workshop chains and large companies

- Unlimited employees

- Multi-site management

- Individual adjustments

- Individual pricing

- From €139/month

CATAMA Unlimited

- Tailor-made complete solution

- Dedicated support

- Individual developments

- Premium service level

- Upon request

Detailed information on all CATAMA editions and prices can be found on the official product page.

ROI calculation: When does CATAMA pay off?

Investing in professional workshop software typically pays for itself within 3-6 months. Let's look at a specific example:

Example workshop:

- 6 mechanics

- Average hourly rate: €95

- Current occupancy rate: 70%

- CATAMA Professional Suite: €149/month

Savings and increased revenues:

| Area | improvement | Monthly value |

|---|---|---|

| Capacity utilization increase (+12%) | 96 additional billable hours | +9.120€ |

| Reduced planning time | 28 hours/month saved | +2.660€ |

| Avoided incorrect bookings | 8 appointments/month | +1.520€ |

| Faster billing | 2 days earlier | +800€ |

| Total added value | +14.100€ | |

| Less CATAMA costs | -149€ | |

| Net profit | +€13,951/month |

Even with a conservative calculation using only 50% of these values, this results in a monthly added value of almost €7,000 – that corresponds to an ROI of over 4,600%.

Free trial and onboarding

CATAMA offers free trial access to evaluate the software risk-free:

Benefits of the trial phase:

- ✅ 14 days full functionality

- ✅ No credit card required

- ✅ Personal introduction by the support team

- ✅ Import of existing data possible

- ✅ Individual training for employees

The onboarding process is structured and practice-oriented:

- Day 1-2: System configuration and basic settings

- Days 3-5: Staff and resource setup

- Days 6-8: Employee training

- Days 9-12: Parallel operation with the old system

- Days 13-14: Complete migration

Compliance and data security

GDPR compliance and data protection

As a German software solution, CATAMA meets the requirements of the General Data Protection Regulation (GDPR):

Privacy features:

- 🔒 Server location in Germany

- 🔒 End-to-end encryption

- 🔒 Role-based access rights

- 🔒 Audit logs for traceability

- 🔒 Data protection impact assessment carried out

All details can be found in CATAMA's privacy policy

Industry-specific compliance

Automotive businesses are subject to specific legal requirements, which CATAMA takes into account:

Retention obligations:

- Documentation of removed old parts

- Archiving of workshop orders (6 years)

- Invoice archiving (10 years)

- Warranty and guarantee documentation

Working Time Act:

- Automatic break control

- Maximum working time monitoring

- Rest period compliance

- Sunday work documentation

Environmental regulations:

- Waste oil documentation

- Hazardous Materials Management

- Disposal certificate archiving

The industry-specific software for automotive workshops ensures that all legal requirements are met automatically.

Practical examples: Success stories from the industry

Case Study 1: Medium-sized workshop increases capacity utilization by 28%

Initial situation:

Auto-Service Schmidt in Hamburg operates a workshop with 8 mechanics and struggled with inefficient planning. Appointments were managed in an Excel spreadsheet, and time tracking was done on paper slips.

Challenges:

- Average occupancy only 65%

- 15-20 double bookings per month

- Invoicing was delayed by 5-7 days

- No transparency regarding employee productivity

CATAMA Implementation:

After a 2-week introduction, the CATAMA Professional Suite was fully implemented.

Results after 6 months:

- ✅ Occupancy rate rose to 93%

- ✅ Double bookings virtually eliminated

- ✅ Invoices are generated on the same day

- ✅ Order processing time reduced by 18%

- ✅ Customer satisfaction (NPS) increased from 42 to 68

Managing Director Thomas Schmidt: “The investment paid for itself after just 4 months. The time savings are particularly impressive – I now spend 90% less time on planning tasks and can concentrate on strategic issues.”

Case Study 2: Workshop Chain Optimizes Multi-Site Operation

Initial situation:

The AutoPro Group operates 5 workshops in southern Germany with a total of 35 employees. Each location used different systems; central control was not possible.

Challenges:

- No cross-site resource planning

- Different processes at each location

- No consolidated evaluations

- Difficult personnel planning in case of illness

CATAMA implementation:

Gradual rollout of the CATAMA Enterprise Suite at all 5 locations over 3 months.

Results after 12 months:

- ✅ Central planning and control of all locations

- ✅ Flexible workforce planning across locations

- ✅ Consolidated key figures and benchmarking

- ✅ 22% reduction in administrative costs

- ✅ Uniform processes and quality standards

Future-proof technology for 2026 and beyond

Continuous development

CATAMA is constantly evolving. The regular updates demonstrate its commitment to innovation

Current developments (V26-4):

- Integration of vacation planning 2026

- Extended invoicing and quotation fields

- Improved cancellation management

- Optimized calendar functionality

Planned features for 2026:

- AI-powered appointment optimization

- Predictive maintenance integration

- Enhanced mobile app features

- Automatic capacity planning

The fact that updates are included by default[5] means that workshops automatically benefit from all new features – without additional costs or manual upgrade processes.

Future trends in workshop planning

Workshop planning is evolving rapidly. CATAMA prepares workshops for future requirements:

Electromobility:

- Special time slots for high-voltage work

- Qualification tracking for electric vehicle certifications

- Charging infrastructure management

- Battery diagnostics integration

Artificial intelligence:

- Automatic order duration forecasts based on historical data

- Predictive analytics for capacity planning

- Intelligent appointment suggestions

- Anomaly detection in case of time deviations

Customer self-service:

- Online appointment booking with real-time availability

- Transparent status updates during the repair

- Digital vehicle handover

- Automatic service reminders

Sustainability:

- CO2 tracking per order

- Optimization for minimal empty runs

- Resource efficiency indicators

- Sustainability reporting

Frequently asked questions about CATAMA workshop planning

How long does the implementation of CATAMA take?

Basic implementation typically takes 1-2 weeks. For more complex scenarios with individual customizations, 3-4 weeks should be planned. Parallel operation with existing systems is possible.

Can data be imported from other systems?

Yes, CATAMA offers import functions for common formats (CSV, Excel). The support team assists with data migration from legacy systems.

Is employee training required?

Basic training (2-4 hours) is recommended. However, the intuitive user interface allows for quick onboarding. Video tutorials and documentation are available.

How secure is my data?

CATAMA uses German servers with the highest security standards. Daily backups, encryption, and GDPR compliance are guaranteed.

Can I adapt CATAMA to my specific processes?

Yes, CATAMA offers extensive configuration options, for example via the Unlimited version. Furthermore, the Form Builder tool allows you to create custom forms and workflows.

What are the hardware requirements?

As cloud software, CATAMA runs on any modern browser (Chrome, Firefox, Safari, Edge). Tablets are recommended for workshop use and desktop PCs for administrative tasks.

Are there any contract terms?

CATAMA offers flexible contract durations. Monthly cancellation is possible with most plans. Details can be found on the product page .

Comparison: CATAMA vs. traditional planning methods

| criterion | Paper/Whiteboard | Excel/Spreadsheets | CATAMA |

|---|---|---|---|

| Real-time updates | ❌ No | ⚠️ Manual | ✅ Automatic |

| Resource planning | ❌ Very limited | ⚠️ Elaborate | ✅ Automatic |

| Time recording | ❌ Paper slips | ⚠️ Subsequent entry | ✅ Digital & direct |

| Evaluations | ❌ Not possible | ⚠️ Create manually | ✅ Automatic |

| mobility | ❌ Only available on site | ⚠️ Restricted | ✅ Available everywhere |

| Error rate | 🔴 Up | 🟡 Medium | 🟢 Very low |

| Scalability | ❌ Limited | ⚠️ Elaborate | ✅ Unlimited |

| Cost | € Low | € Low | €€ Medium |

| ROI | – | – | 🚀 Very high |

Conclusion: Workshop planning as a competitive advantage

Digital workshop planning with CATAMA will no longer be a luxury in 2026, but a business necessity for successful automotive workshops. The advantages are measurable and significant:

Summary of key benefits:

✅ Increased efficiency: 30-40% time savings in planning tasks

✅ Increased revenue: Up to 28% higher capacity utilization through optimized planning

✅ Cost reduction: Up to 60% reduction in administrative expenses

✅ Improved quality: Error rate drastically reduced through digital processes

✅ Employee satisfaction: Clear structures and fair work allocation

✅ Customer satisfaction: Punctual appointments and transparent communication

✅ Future-proof: Continuous updates and development

The CATAMA Software Suite offers not only workshop planning, but an integrated overall solution for all areas of the automotive business – from inventory management to invoicing to comprehensive management.

Next steps: How to get started with CATAMA

Step 1: Arrange a free demo.

Take advantage of a free trial period to get to know CATAMA without obligation. The support team will guide you through all its features.

Step 2: Conduct a needs analysis.

Analyze your current planning processes and identify the biggest pain points. CATAMA experts will support you in optimizing them.

Step 3: Choose the right edition.

Based on your farm size and requirements, choose the optimal CATAMA edition. Upgrades are possible at any time.

Step 4: Plan the implementation

. Establish a timeline for the rollout. The structured onboarding process minimizes disruption to ongoing operations.

Step 5: Train your team

. Invest in training your employees. Only when the team uses the software optimally will its full potential be realized.

Step 6: Measure success

Define KPIs (utilization, throughput time, customer satisfaction) and regularly measure improvements.

Concluding thoughts

In an increasingly digital world, professional workshop planning the key to success. Workshops that invest in modern software today secure a decisive competitive advantage for years to come.

CATAMA offers not just a software tool, but a platform for continuous process optimization. With regular updates, comprehensive support, and a clear vision for the future of the automotive industry, CATAMA is the ideal partner for forward-thinking workshops.

The question is no longer whether you should digitize – but when you should start. Every day spent on inefficient planning processes costs money, time, and nerves. Seize the opportunity to take your business to the next level.

Contact the CATAMA team today via the official contact page and start your digital transformation. Your workshop, your employees, and your customers will thank you.